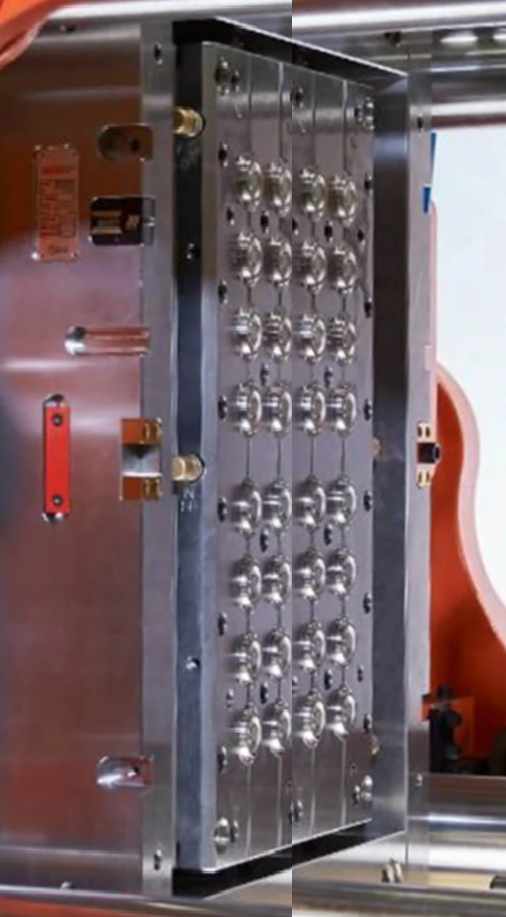

At Innovative Molding (Rieke Packaging), my role as a mechanical engineer was to design a 64 cavity injection mold to meet the demand of producing ½ million enclosures per day for the food and electronics industries.

The biggest challenges were maintaining high-quality standards and designing tools that could run millions of cycles without issues. After reviewing the problems, running FEA, and performing calculations, I modified the design to eliminate a stress concentration on the core, significantly extending the fatigue life of the tools.

These tools were designed and validated, and the injection molding process was established to meet the production demand and quality requirements. The anticipated fatigue issue did not occur during my tenure. This project demonstrated the effectiveness of the design modifications, setting up quality assurance and implementing quality control systems.

Images by Husky, Innovative Molding, and Rieke Packaging

Half a Million Parts Per Day

64 Cavity Stack Injection Mold

1/2 Million a day production throughput

Credit: Innovative Molding

64 Cavity Stack Injection Mold in Action

Video by Husky